As an Amazon Associate I earn from qualifying purchases.

At A Glance

AR-RPM9 is a proprietary stainless steel developed by Artisan Cutlery, known for its impressive balance of toughness, sharpness, and corrosion resistance, making it a good knife steel. It is created using the powder metallurgy process, resulting in a uniform distribution of its nine alloy elements, contributing to its unique characteristics. This steel has a hardness of 58-60HRC and offers superior toughness compared to similar steels like 9Cr18Mov. It is recognized for its commendable edge retention, decent corrosion resistance, high toughness, excellent wear resistance, and high hardness. Compared to other popular knife steels such as D2, 14C28N, AEB-L, and 9Cr18MoV, AR-RPM9 provides good corrosion resistance, ease of sharpening, and toughness. Although it may not compete with premium steels, AR-RPM9 offers a cost-effective option for knife enthusiasts seeking reliable and affordable knives.

AR-RPM9 steel, a proprietary stainless steel manufactured by Artisan Cutlery, has garnered attention in the knife world. Formulated following the powder metallurgy process, this steel is categorized under budget-priced options and is often compared to other common knife steels. The “9” in AR-RPM9 stands for nine elements present in its alloy composition, contributing to its unique characteristics.

As knife owners look for the perfect balance between toughness, sharpness, and corrosion resistance, AR-RPM9 stands as a contender in the world of knife steels. Its powder metallurgy formulation results in a more uniform distribution of alloying elements, which can lead to improved mechanical properties. However, it’s important to know how it fares when compared to other available options in the market.

In this article, we will discuss the properties of AR-RPM9 steel, its performance, and whether it is a good option for knife enthusiasts. By understanding its advantages and drawbacks, you can make an informed decision when selecting the right knife steel for your needs.

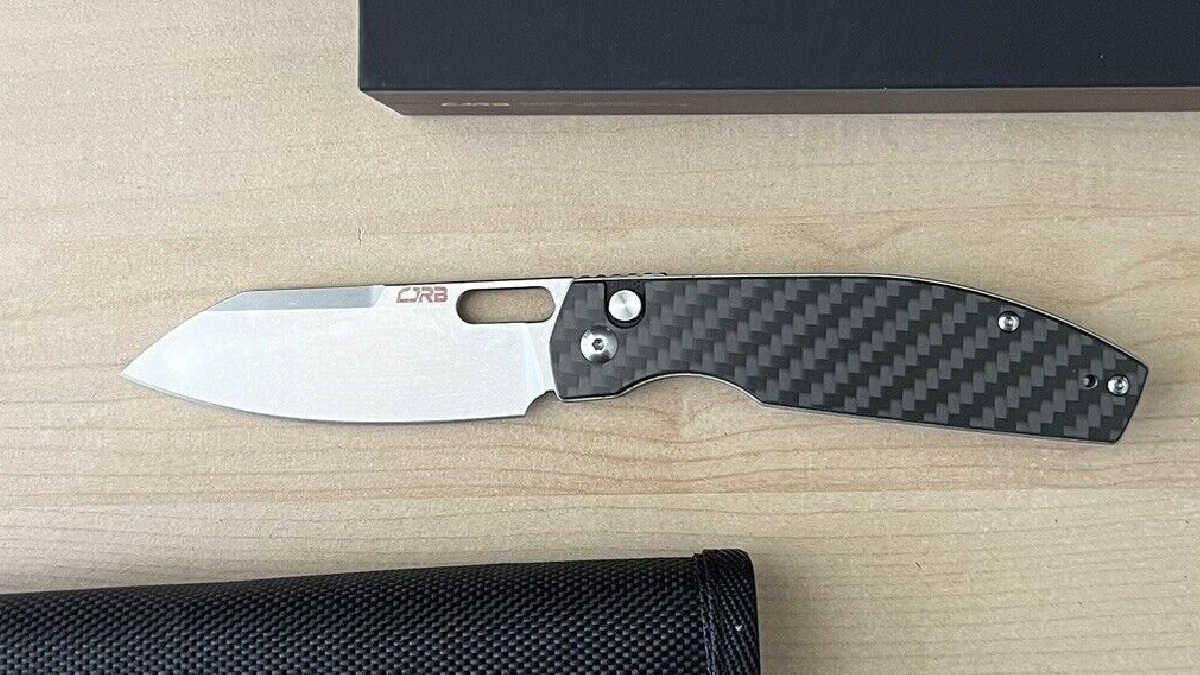

My Favorite Knife That Uses AR-RPM9 Steel

AR-RPM9 Steel Overview

AR-RPM9 steel is a proprietary stainless steel manufactured by Artisan Cutlery, which uses a powder metallurgy process. It is designed for their budget-priced knives and falls under their CJRB lineup. The ‘9’ in the name signifies the elements present in its alloy composition, including carbon, chromium, molybdenum, and vanadium.

This steel offers a balance between edge retention, corrosion resistance, and relatively easy sharpening. It features a hardness of 58-60HRC, which is typical for decent quality knife steels. Being produced using powder metallurgy, AR-RPM9 has a more uniform and refined microstructure compared to standard ingot-based steels, lending it better toughness than similar steels like 9Cr18Mov.

One popular model utilizing AR-RPM9 steel is the CJRB Ria, featuring a 2.95″ drop point blade with a thickness of 0.10″. The knife uses a manual thumb stud opener, and the action is smooth because it rides on ceramic ball bearing pivots. The Ria is a liner lock knife with OD green micarta handle scales mounted on stainless steel liners, ensuring durability and longevity.

While the AR-RPM9 steel may not compete with premium steel offerings, it does provide a cost-effective solution for knife enthusiasts seeking affordable and reliable knife options. As a result, Artisan Cutlery and CJRB knives are gaining popularity in the knife community, providing an alternative for those looking to try quality knives without breaking the bank.

Keep in mind that proper maintenance and care are essential for any knife, regardless of the steel type. Ensure that your AR-RPM9 steel blades are cleaned and lubricated regularly, sharpened when necessary, and stored in a dry environment to make the most out of their performance and longevity.

Performance and Properties

AR-RPM9 is a high-performance knife steel, offering a range of desirable properties for knives used in various applications. This section delves into the various characteristics of AR-RPM9 steel, particularly edge retention, corrosion resistance, toughness, wear resistance, and hardness.

Edge Retention

The edge retention of AR-RPM9 steel is commendable, especially considering its composition, which includes a high carbon content and the presence of vanadium and cobalt. This combination of elements improves its ability to maintain a sharp edge during use. The impressive edge retention of AR-RPM9 steel is perfect for everyday tasks requiring a consistently sharp blade.

Corrosion Resistance

AR-RPM9 steel has a decent amount of corrosion resistance, which is an essential feature for knives used outdoors or in wet conditions. Its composition consists of chromium, which increases its ability to withstand oxidation and prevent rusting. The corrosion-resistant quality of AR-RPM9 steel helps prolong the life of the blade and ensures it performs optimally.

Toughness

Another crucial factor to consider when assessing knife steel is toughness. In this regard, AR-RPM9 stands out for its higher toughness than D2 steel. This means it can handle more impact and pressure without breaking or deforming. The high toughness of AR-RPM9 steel is attributed to its composition, which includes vanadium, molybdenum, and niobium. These elements significantly contribute to the steel’s ability to resist chipping and breaking.

Wear Resistance

The wear resistance of a knife steel indicates how well it can withstand abrasion and maintain its edge over time. AR-RPM9 steel is known for its excellent strength, hardness, and durability, making it ideal for applications where strength and durability are essential. Its wear resistance ensures the blade maintains its performance even after frequent use.

Hardness

Lastly, the hardness of AR-RPM9 steel is measured at 58-60HRC on the Rockwell hardness scale. This high hardness level is typically found in high-end knives from reputable brands such as Cold Steel or Spyderco. The high hardness is a direct result of its carbon content and the inclusion of vanadium and cobalt in its composition, which further contributes to the overall performance of the steel.

Comparison with Other Steels

In this section, we will compare AR-RPM9 steel to other popular knife steels such as D2, 14C28N, AEB-L, and 9Cr18MoV.

AR-RPM9 vs D2 Steel

AR-RPM9 is a high-carbon, stain-resistant steel that benefits from powder metallurgy (PM) technology, making it easy to sharpen. In contrast, D2 is a semi-stainless tool steel with high wear resistance and good edge retention. Let’s consider some differences:

- Corrosion Resistance: AR-RPM9 has better corrosion resistance due to its 18% chromium content, while D2 has a lower chromium content (11-12%).

- Ease of Sharpening: AR-RPM9 is reportedly easier to sharpen compared to D2, which can be more challenging to maintain.

- Edge Retention: D2 generally has better edge retention due to its higher hardness, whereas AR-RPM9 focuses on ease of sharpening and stain resistance.

AR-RPM9 vs 14C28N

Comparing AR-RPM9 to 14C28N, a Swedish stainless steel developed specifically for knives, we can observe some differences:

- Corrosion Resistance: Both steels have good corrosion resistance, with 14C28N containing around 14% chromium and AR-RPM9 having 18% chromium.

- Edge Retention: 14C28N is known for its excellent edge retention due to its fine-grained structure, while AR-RPM9 is more focused on stain resistance and ease of sharpening.

- Sharpening Ease: AR-RPM9 is considered easier to sharpen, whereas 14C28N may require slightly more effort.

AR-RPM9 vs AEB-L

AEB-L is a high-quality, fine-grained stainless steel known for its outstanding toughness and edge stability. When comparing it to AR-RPM9, we can note some differences:

- Corrosion Resistance: AEB-L and AR-RPM9 both offer good corrosion resistance due to their high chromium content (approximately 13% in AEB-L and 18% in AR-RPM9).

- Edge Retention: AEB-L is known for superior edge stability, while AR-RPM9 prioritizes stain resistance and sharpening ease.

- Sharpening Ease: AR-RPM9 is recognized for being easy to sharpen, while AEB-L may require more effort and skill to maintain its edge.

AR-RPM9 vs 9Cr18MoV

Lastly, comparing AR-RPM9 to 9Cr18MoV, a Chinese stainless steel, reveals some key differences:

- Corrosion Resistance: Both steels have similar corrosion resistance due to their high chromium content (approximately 18% for both AR-RPM9 and 9Cr18MoV).

- Edge Retention: 9Cr18MoV has decent edge retention, but AR-RPM9 steel may have improved toughness due to the powdered metallurgy process.

- Sharpening Ease: AR-RPM9 is known for its ease of sharpening, while 9Cr18MoV may be slightly more challenging to maintain.

In conclusion, AR-RPM9 offers a good balance of corrosion resistance, ease of sharpening, and toughness compared to other steels like D2, 14C28N, AEB-L, and 9Cr18MoV.

Sharpening Recommendations

AR-RPM9’s sharpening process is relatively similar to that of 9Cr18Mov, which is a solid budget knife steel considered an analogue to 440c.

Since knives made of AR-RPM9 steel are budget-centric, it is crucial to use budget sharpening stones to complement the overall affordability aspect of these knives. Follow these sharpening recommendations for AR-RPM9 steel:

- Sharpness retention: Monitor the knife’s performance and sharpen it when necessary. This will help maintain a sharp edge over extended periods of use.

- Sharpening angle: Maintain a 15-20 degree angle per side for proper edge geometry. This angle range ensures good cutting performance and edge stability.

- Abrasive selection: Use budget-friendly sharpening stones or systems. Some options include aluminum oxide, silicon carbide, and diamond stones.

- Sharpening technique: Start with a coarser grit to set the edge geometry and then progress to finer grits to polish and refine the edge. Finish with stropping or honing to remove any remaining burr.

Overall, a well-executed heat treatment and sharpening regime will ensure that your AR-RPM9 knife remains sharp, durable, and efficient in a variety of tasks while maintaining its budget-friendly nature.

Ideal Applications

AR-RPM9 steel is a proprietary stainless steel manufactured by Artisan Cutlery. It is known for its fine grain structure, which translates to better performance in most uses. Due to its properties, AR-RPM9 steel is well-suited for a variety of applications.

Everyday Carry (EDC) Knives: This steel is a great choice for EDC knives as it offers a good balance of edge retention, toughness, and resistance to corrosion. The higher hardness rating of AR-RPM9 also ensures that it can hold an edge longer than its competitors such as D2 steel, making it suitable for daily cutting tasks.

CJRB Tactical Knife: AR-RPM9 steel is also used in CJRB knives, a popular brand known for producing quality tactical blades. The CJRB Crag and Artisan Cutlery Arroyo are two examples of knives featuring AR-RPM9 steel that have performed well in various cutting tasks. The CJRB Ria is another great example of a budget-friendly knife crafted from AR-RPM9 steel.

Outdoor Activities: The properties of AR-RPM9 steel make it an excellent choice for knives and tools used in camping, hunting, and fishing. Its ability to hold an edge and resist rust makes it ideal for these situations, where exposure to moisture and consistent use can be expected.

Heavy-Duty Applications: The increased toughness and resistance to chipping make AR-RPM9 an optimal choice for heavy-duty applications. Knives made from this steel can endure harsh conditions and demanding tasks without breaking or losing their sharpness.

In summary, AR-RPM9 steel is a versatile material suitable for a wide range of applications, including everyday carry knives, CJRB tactical knives, outdoor activities, and heavy-duty jobs. Its properties allow for exceptional edge retention, toughness, and resistance to wear and corrosion, making it an excellent choice for various knife uses.

Conclusion

AR-RPM9 is a proprietary steel developed by Artisan Cutlery using the powder metallurgy process. This process offers a more uniform distribution of alloy elements, leading to improved performance in areas such as edge retention, toughness, and corrosion resistance.

As a budget steel, AR-RPM9 presents an interesting choice. Although it may not directly compete with premium steels in terms of performance, it does provide an upgrade from traditional budget steels like 9Cr18Mov. Knives made from AR-RPM9, such as the CJRB Ria, offer a ceramic ball bearing pivot, stainless steel liners, and a hardness of 58-60HRC. This combination makes them suitable for everyday use and various outdoor activities.

Using powder metallurgy in a budget knife steel is a strategic move by Artisan Cutlery, as it differentiates their products from others in the same price range. Although specific data on AR-RPM9’s composition and performance are not widely available, initial impressions from users suggest that it should hold its own compared to other steels in its price bracket.

In summary, AR-RPM9 is an innovative budget knife steel that leverages the advantages of the powder metallurgy process to deliver a solid performance at a more accessible price point. While not directly comparable to high-end steels, it offers a compelling option for those who desire decent quality without breaking the bank.

Do Sheepsfoot Blades Have A Purpose? (Cuz They’re Ugly…)

Spetsnaz Machetes – Blades Of The Russian Special Forces

What Is The Actual Purpose Of A Spear Point Knife Blade?

CRKT CEO Review – Coolest, Most Worthless Knife Ever?

How Sharp Is A Scalpel? (Is It Sharper Than A Razor?)

Can You Shave With A Knife? (Yes, Here’s How)

As an Amazon Associate I earn from qualifying purchases.