Last updated on August 30th, 2023 at 03:47 am

As an Amazon Associate I earn from qualifying purchases.

Knife Steel Guide

Hardest Knife Steel • 5 Best Knife Steels • Best Budget Knife Steel • Carbon vs Stainless Steel • Worst Knife Steel

Knife Steel Directory (Profiles & Reviews)

CPM-20CV • S30V • S35VN • S45VN • S90V • S110V • 420HC • 420J2 • 440C • 3G • A2 • D2 • H1 • M4 • SK-5 • VG10 • K110 • M390 • M390MK • AUS 8 • AUS 10 • 154CM • CPM154 • 15N20 • N690 • 1055 • 1075 • 1095 • 4116 • 5160 • 52100 • Ar-RPM9 • AEB-L • ATS 34 • RWL 34 • ZDP-189 • 12C27 • 14C28N • 80CrV2 • 5Cr15MoV • 7CR17MoV • 8Cr13MoV • 9Cr18MoV • X50CrMoV15 • CPM-3V • CPM-4V • CTS 204P • CTS BD1N • CTS XHP • Tru-Sharp • 420 Stainless • Elmax • MagnaCut • Nitro-V • CruWear • Chrome Vanadium

I’m going to start off this guide with a disclaimer: despite being personally obsessed with knife steel, I don’t think that the choice matters very much for the average knife user. Despite my nerdy love for different steels (and my need to own a knife with every single one of them) the type of steel that makes up a blade has very little to do with what I carry on a daily basis.

So, in short, the truth about knife steel is that it is less important than the brand/quality of a knife, its ergonomics, scale/handle material, blade shape, and just about everything else.

So, if you’re here to nerd out, join me! If you’re just here to pick a great tool, choose the one that you like the look of best as you’re more likely to carry it, and, in all likelihood, it will be good enough.

Knife steel is a crucial aspect of any cutting tool, determining its performance, durability, and overall quality. In its basic form, steel is a combination of iron and carbon, but various elements have been added and refined over time to create steel types specifically suited for particular applications, such as knives. The choice of knife steel can greatly impact a blade’s edge retention, corrosion resistance, and sharpening ease, making it essential to understand the different types available and their unique properties.

Still here? Awesome! So, this article will serve as a guide to navigating the vast world of knife steels and their various compositions. It will cover the important factors that should be considered when selecting a knife steel, such as hardness, toughness, and resistance to wear and corrosion. Additionally, it will provide insight into the different tiers of knife steel quality, from low to premium options, to help readers make informed decisions when purchasing or maintaining a knife.

With a solid understanding of knife steel properties and their significance, finding the perfect blade for your needs becomes a less daunting task. By examining the most popular types of knife steel and comparing their compositions, this guide aims to provide a comprehensive resource to enhance your knowledge and inform your decisions in the exciting world of cutting tools.

Table of Contents

Understanding Knife Steel

Composition and Elements

Knife steel is an alloy that primarily consists of iron and carbon, with additional elements added to the mix to create specific characteristics such as hardness, sharpness, and corrosion resistance. Some of the common elements found in knife steel include chromium, vanadium, molybdenum, nickel, nitrogen, tungsten, cobalt, manganese, silicon, copper, niobium, phosphorus, and sulfur. Each of these elements contributes to the overall performance of the knife, and their presence in varying amounts can significantly affect the properties of the steel.

Carbon

Carbon is the primary element in all forms of steel, typically present at levels ranging from 0.5% to 1.5%. It is responsible for increasing the hardness and strength of the steel. High carbon steel is known for its excellent edge retention and ability to hold a sharp edge. However, higher amounts of carbon also make the steel more brittle, prone to chipping, and more susceptible to corrosion.

Chromium and other Alloying Elements

Chromium is another critical element in knife steel, as it imparts a crucial level of corrosion resistance. A steel composition containing a minimum of 10.5% chromium is considered to be stainless steel. Chromium also aids in hardening the steel and improving its wear resistance.

Other alloying elements such as vanadium, molybdenum, nickel, nitrogen, tungsten, cobalt, manganese, silicon, copper, niobium, phosphorus, and sulfur perform various roles in enhancing the steel’s performance. For example:

- Vanadium strengthens the steel, enhances its wear resistance, and refines its grain structure, resulting in a sharper and more durable edge.

- Molybdenum improves the steel’s hardenability, strength, and overall toughness, making it more resistant to breakage.

- Nickel increases the steel’s ductility and toughness, making it less prone to cracking.

- Nitrogen raises the steel’s hardness and corrosion resistance without compromising its toughness.

- Tungsten helps strengthen the steel, increase its wear resistance, and create a fine grain structure.

In conclusion, understanding the composition of knife steel can provide valuable insight into the steel’s properties and performance, including its hardness, strength, corrosion resistance, and ability to hold an edge. By being aware of the specific roles of elements like carbon and chromium, as well as various additional alloying elements, one can make informed decisions about the best type of steel for their desired application.

Types of Knife Steel

Carbon Steel vs Stainless Steel

Carbon steel and stainless steel are the two primary categories of knife steels. Carbon steel is an alloy that mainly consists of iron and carbon, while stainless steel also contains at least 10.5% chromium (although most manufactured stainless is around 15%), which provides enhanced resistance to corrosion. Carbon steel knives are generally known for their sharpness and ease of sharpening, while stainless steel knives offer increased durability and low maintenance due to their resistance to rust.

Tool and High Carbon Steels

Tool steels and high carbon steels are both subsets of carbon steel. Tool steels are designed for durability and abrasion resistance and are commonly used in cutting and shaping tools. Some popular tool steel types for knives include D2 and O1. High carbon steels, on the other hand, contain a higher percentage of carbon than typical carbon steels. Examples of high carbon steels used in knives are 1095 and 52100. These steels are known for their hardness and ability to hold an edge but may require more maintenance due to their susceptibility to rust.

High-End and Super Steels

High-end steels and super steels are terms often used to describe premium stainless steel types that offer exceptional performance in terms of edge retention, corrosion resistance, and toughness. These steels usually contain a mix of additional elements like vanadium, molybdenum, and cobalt to enhance their properties. Some examples of high-end steels are VG10 and CPM154.

Super steels, such as CPM S110V, CPM S90V, and M390, are produced using advanced manufacturing techniques like powder metallurgy, which enables a more uniform distribution of elements within the steel matrix. This results in a superior combination of properties compared to traditional steels, but also comes with a higher price tag.

Each type of knife steel has its own characteristics and suitability for different applications. When choosing a knife, consider factors like hardness, edge retention, corrosion resistance, and ease of sharpening to determine which steel best aligns with your needs.

Popular Knife Steel Grades

Basic Steels: 420 and 420HC

The 420 and 420HC steel grades are basic steels commonly used for knives and offer a balance between affordability and performance. These steels are corrosion-resistant, but do not have exceptionally high hardness or edge retention. They are ideal for budget-friendly everyday knives that require minimal maintenance.

Some popular knives using these steels are:

- 420 steel:

- 420HC steel:

Mid-Range Steels: AUS, VG and ATS-34

The mid-range steels category includes AUS, VG, and ATS-34 steel grades. These steels are well-balanced in terms of toughness, corrosion resistance, and edge retention, making them suitable for a wide range of knife applications.

- AUS series (AUS-6, AUS-8, AUS-10): Known as Japanese stainless steels, the AUS series provides a good balance between strength, corrosion resistance, and edge retention. The AUS-8 and AUS-10, being the most popular choices, are used in many EDC and tactical knives. Some notable examples are:

- Cold Steel AD-10 LITE (AUS-10A)

- SOG Twitch II (AUS-8)

- VG series (VG-1, VG-10): The VG series offers excellent edge-holding capabilities and corrosion resistance. VG-10, in particular, is known for its sharpness and is popular in Japanese kitchen knives.

- Spyderco Dragonfly 2 (VG-10)

- Fallkniven S1 (VG-10)

- ATS-34: Known for its edge retention and corrosion resistance, ATS-34 is commonly seen as a cost-effective alternative to 154CM steel. It is commonly found in high-quality folding and fixed blade knives.

- GT Knives EDC Utility (ATS-34)

High-End Steels: CPM and Crucible Series

The high-end steels category includes the CPM and Crucible series of steels, which offer excellent cutting performance, edge retention, and corrosion resistance. These steels are ideal for premium knives, demanding users, or heavy-duty applications.

- CPM series (CPM-M4, CPM-3V, CPM-S90V, CPM-S110V, CPM-20CV, CPM M2, CPM 154, CPM 20CV): Known for their uniform composition, these steels exhibit consistent performance throughout the blade. They are produced through a powder metallurgy process, leading to exceptional toughness and edge stability. Some examples of knives using CPM series steels include:

- Spyderco Para Military 2 (CPM-S110V)

- Zero Tolerance Hinderer CF (CPM-20CV)

- Crucible Series (CTS series, such as CTS-204P, CTS-XHP, CTS-BD1): The Crucible series offers high-performance steels designed for demanding applications. These steels are known for their exceptional edge retention, corrosion resistance, and overall performance. Some popular knives using this steel series are:

- Spyderco Chaparral Prestige (CTS-XHP)

- Spyderco McBee Specialty (CTS-XHP)

Key Properties (With Knife Steel Chart)

So, if we’re going to compare knife steels, it’s important that we lay some sort of groundwork so we know what to compare them on. In my opinion, there are 5 (or maybe 6) characteristics that make a great knife steel.

Here are some factors to consider when choosing a blade steel for your knife:

- Edge Retention: The ability of the steel to maintain a sharp edge during use.

- Corrosion Resistance: The steel’s resistance to rust and damage from various environmental factors.

- Rockwell Hardness: A measure of the steel’s hardness, which can affect edge retention and wear resistance.

- Wear Resistance: The steel’s ability to resist abrasion and wear during use.

- Toughness: The steel’s resistance to chipping, cracking, or breaking under stress.

| Steel | Maker | Typical Hardness (HRC) | Notable Properties | Chemical Composition (approx.) | Popular Knife Makers |

|---|---|---|---|---|---|

| AUS-8 | Aichi Steel | 57-59 | Balanced toughness, sharpness, and corrosion resistance | 0.75% C, 1% Mn, 14% Cr, 0.49% Mo, 0.2% V | SOG, Cold Steel, Ontario Knife Company |

| VG-10 | Takefu Special Steel | 59-61 | Excellent hardness and corrosion resistance | 1% C, 0.5% Mn, 15% Cr, 1% Mo, 0.2% V, 1.5% Co | Spyderco, Mcusta, Fallkniven |

| 154CM | Crucible Industries | 58-61 | High hardness and edge retention | 1.05% C, 0.5% Mn, 14% Cr, 4% Mo, 0.3% V | Benchmade, Gerber, Buck Knives |

| D2 | Various | 55-62 | Excellent wear resistance | 1.5% C, 0.3% Mn, 12% Cr, 0.9% Mo, 0.9% V | Benchmade, Ontario Knife Company, SOG |

| CPM S30V | Crucible Industries | 59-61 | Great edge retention and durability | 1.45% C, 0.5% Mn, 14% Cr, 4% Mo, 2% V | Spyderco, Benchmade, Buck Knives |

| CPM S35VN | Crucible Industries | 59-61 | Great edge retention, durability, and improved toughness | 1.4% C, 14% Cr, 3% Mo, 2% V, 0.5% Nb | Chris Reeve Knives, Spyderco, Benchmade |

| 440C | Various | 56-59 | Good balance of hardness, toughness, and edge retention | 1.1% C, 17% Cr, 0.5% Mo | Boker, Schrade, Buck Knives |

| 1095 | Various | 56-58 | High toughness, easy sharpening | 0.95% C, 0.4% Mn | ESEE, KA-BAR, Ontario Knife Company |

| CPM 3V | Crucible Industries | 58-60 | High toughness, good wear resistance | 0.8% C, 7.5% Cr, 2.75% Mo, 1.3% V | Bark River Knives, Spyderco, Benchmade |

| M390 | Bohler-Uddeholm | 60-62 | High wear resistance, excellent corrosion resistance | 1.9% C, 20% Cr, 1% Mo, 4% V, 0.6% W | Benchmade, Zero Tolerance, LionSteel |

| Elmax | Uddeholm | 58-61 | High wear resistance, corrosion resistance | 1.7% C, 18% Cr, 1% Mo, 3% V, 0.8% Mn | Microtech, LionSteel, Benchmade |

| H1 | Myodo Metals | 57-58 | Exceptional corrosion resistance | 0.15% C, 16.5% Cr, 6% Ni, 1% Mo, 0.10% N | Spyderco |

| CTS-XHP | Carpenter Technology | 59-62 | High hardness, good toughness and edge retention | 1.6% C, 16% Cr, 0.6% Ni, 0.4% Mn, 0.45% Mo, 0.8% V | Cold Steel, Spyderco, Custom Makers |

| N690 | Bohler-Uddeholm | 58-60 | Good sharpness and ease of maintenance | 1.07% C, 17% Cr, 1.1% Mo, 1.5% V, 0.4% Co | Fox Knives, Extrema Ratio, Boker |

| AEB-L | Uddeholm | 57-59 | Excellent edge retention and toughness | 0.67% C, 13% Cr, 0.6% Mo, 0.4% V, 0.07% N | Custom Makers, Boker |

| 52100 | Various | 60-64 | Excellent edge retention and toughness | 1% C, 1.4% Mn, 0.35% Cr | Bark River Knives, Custom Makers |

| LC200N | Zapp Precision Metals | 57-59 | Exceptional corrosion resistance and toughness | 0.3% C, 15.5% Cr, 0.5% Mo, 0.5% Ni, 0.10% N | Spyderco, Benchmade |

| CPM 20CV | Crucible Industries | 59-61 | Excellent wear resistance and corrosion resistance | 1.9% C, 20% Cr, 1% Mo, 4% V | Benchmade, Zero Tolerance, LionSteel |

| CPM M4 | Crucible Industries | 62-64 | Outstanding toughness and edge retention | 1.42% C, 5.5% Cr, 5.25% Mo, 4.5% V, 0.8% Mn, 0.3% Si | Benchmade, Spyderco |

| RWL34 | Damasteel AB | 58-61 | Balanced hardness, toughness, and corrosion resistance | 1.05% C, 14% Cr, 4% Mo, 0.2% V | Benchmade, Custom Makers |

Hardness and Edge Retention

Knife steel hardness is measured on the Rockwell Scale (HRC), and it indicates the steel’s ability to resist deforming when subject to stress and applied forces. A higher HRC rating generally leads to better edge retention, as the steel can maintain its sharpness for an extended period. However, excessively hard steel can become brittle and prone to chipping. It’s essential to find a balance between hardness and toughness to achieve optimal performance in a knife.

Toughness and Impact Resistance

Toughness in knife steel refers to its capacity to absorb energy and resist fracturing under stress, such as impacts and bending. High toughness is crucial for knives that withstand heavy use or need to resist impacts, like chopping or splitting. Depending on the intended purpose of the knife, a balance between hardness and toughness is necessary to ensure the blade doesn’t chip or break during use.

Wear and Corrosion Resistance

Wear resistance is the ability of the steel to withstand damage from abrasive and adhesive wear, while corrosion resistance refers to the steel’s ability to resist rust and other forms of oxidation. These properties are essential for knives exposed to harsh environments, moisture, or acidic substances.

- Wear Resistance: Steels with high wear resistance often contain carbides that help protect the blade from abrasion. A knife with good wear resistance will remain functional for a longer time without the need for continuous maintenance.

- Corrosion Resistance: Stainless steels with a higher chromium content typically offer better corrosion resistance, but they may sacrifice some hardness or toughness in return. Finding the right balance for your specific needs is crucial when selecting a knife steel with proper corrosion resistance.

Ease Of Sharpening

The ease of sharpening is an essential property to consider when selecting a knife steel. Some steels can be challenging to re-sharpen once they lose their edge, while others may be easier to maintain. Generally, harder steels with higher edge retention take more time and effort to sharpen, but they will require sharpening less frequently.

Price

The price of a knife is often influenced by the type of steel used. High-performance steels with excellent edge retention, toughness, and corrosion resistance tend to be more expensive due to their advanced metallurgical properties. However, more affordable steels may still be suitable for everyday tasks, depending on their intended use. It’s essential to weigh the price against the desired properties of the knife steel and consider your specific needs when choosing the right knife.

Now, if you want to things displayed a bit more simply, here are how the 10 most popular knife steel stack up against each other. Note that I ranked these from 1-10 relative only to the 10 steels shown here. So a “1” in toughness, for example, only means that steel is the toughest among the 10 listed here.

| Steel Type | Toughness (Rank) | Hardness (Rank) | Ease Of Sharpening (Rank) | Edge Retention (Rank) | Cost (Rank) |

|---|---|---|---|---|---|

| 1095 Carbon | 2 | 7 | 1 | 9 | 2 |

| VG-10 | 6 | 8 | 4 | 6 | 4 |

| 154CM | 7 | 5 | 6 | 7 | 6 |

| S30V | 5 | 4 | 9 | 3 | 8 |

| D2 | 8 | 6 | 10 | 4 | 5 |

| AUS-8 | 9 | 10 | 2 | 10 | 1 |

| CPM-M4 | 3 | 2 | 8 | 2 | 10 |

| Elmax | 4 | 3 | 7 | 5 | 9 |

| H1 | 1 | 9 | 3 | 8 | 7 |

| M390 | 10 | 1 | 5 | 1 | 3 |

Metric Descriptions for Rankings:

- Toughness (Rank): Ranked from 1 (most tough) to 10 (least tough) among these steels.

- Hardness (Rank): Ranked from 1 (hardest) to 10 (least hard) among these steels.

- Ease Of Sharpening (Rank): Ranked from 1 (easiest to sharpen) to 10 (hardest to sharpen) among these steels.

- Edge Retention (Rank): Ranked from 1 (best edge retention) to 10 (worst edge retention) among these steels.

- Cost (Rank): Ranked from 1 (most cost-effective) to 10 (least cost-effective) among these steels.

Knife Steel in Practice

Blade Shape and Geometry

When considering knife steel, it is essential to understand the blade shape and geometry. Different blade steels perform better with specific blade shapes and edge geometries, which can influence the knife’s performance and, ultimately, its use.

For example, if a blade steel is known for excellent edge retention but is more difficult to sharpen, it may be suited for a knife with a simple blade shape, such as a drop point or clip point, to make the sharpening process less complicated. On the other hand, steels with excellent corrosion resistance are suitable for knives with more intricate blade shapes, as they may come into contact with moisture and other corrosive elements.

Sharpening and Maintaining Your Knife

Proper sharpening and maintenance are essential in ensuring that your knife remains useful and efficient for a long time. Different blade steels may require different sharpening techniques or frequencies, depending on their characteristics.

For instance, steels with excellent edge retention may not need to be sharpened as often. However, when the time comes to sharpen them, they may require more effort or specialized equipment, due to their increased hardness. In contrast, softer steels may require more frequent sharpening, but the process is usually more straightforward and quicker.

To maintain your knife, it’s essential to perform the following tasks:

- Regular Sharpening: Keep your knife sharp by using the appropriate sharpening method for your blade steel, such as a whetstone, diamond stone, or ceramic rod.

- Cleaning: Clean your knife regularly to remove any dirt, debris, or corrosive materials from the blade and handle. It is crucial to dry the knife thoroughly, especially if the steel has lower corrosion resistance.

- Lubrication: Apply a thin layer of oil to your knife’s pivot and blade to prevent corrosion and ensure smooth operation.

- Storage: Store your knife in a dry environment, such as a knife roll, case, or sheath, to minimize exposure to moisture.

In summary, understanding your knife’s blade steel and its properties can greatly help with choosing the ideal blade shape, edge geometry, and sharpening and maintenance methods. With proper care and attention, you can ensure that your knife performs optimally and lasts a long time.

Selecting the Right Steel for Your Knife

Balancing Trade-Offs and Performance

Selecting the right steel for your knife involves understanding the trade-offs between various performance aspects. These include hardness, corrosion resistance, and edge retention. Different steels have unique properties that make them suitable for specific tasks and users. When choosing a steel, consider the intended purpose of the knife and the environment in which it will be used.

Steel composition plays a crucial role in determining a knife’s performance. Carbon steel, stainless steel, high carbon stainless steel, and Damascus steel are all excellent choices for making knives, each with their distinct advantages:

- Carbon steel: Known for its hardness and durability, carbon steel is ideal for heavy-duty tasks. However, it can be prone to rust and requires proper care to maintain its performance.

- Stainless steel: With high corrosion resistance, stainless steel is perfect for use in wet environments. However, it may not retain its edge as well as carbon steel.

- High carbon stainless steel: A combination of carbon and stainless steel, this steel offers a balance between hardness and corrosion resistance, providing an excellent middle ground for many knife uses.

- Damascus steel: Composed of multiple layers, Damascus steel is known for its unique appearance and excellent edge retention. However, it can be more expensive and harder to maintain.

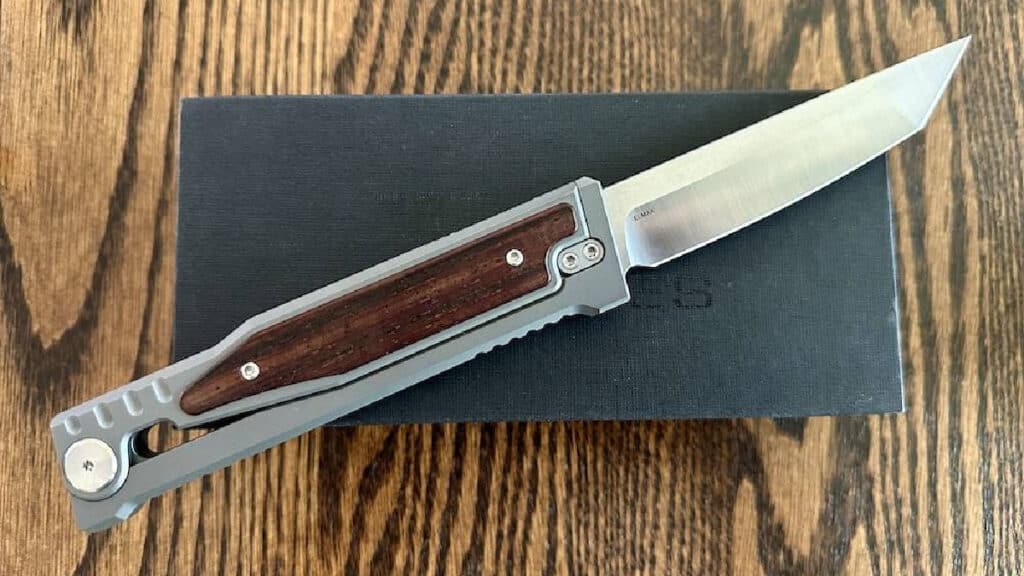

Fixed Blades vs Pocket Knives

The choice between fixed blades and pocket knives also influences the decision on steel selection. Fixed blade knives are usually larger, making them ideal for heavy-duty tasks where durability and edge retention are paramount. In this case, carbon steel or high carbon stainless steel might be the best choice.

Pocket knives, on the other hand, prioritize portability and versatility. They are typically used for everyday tasks where corrosion resistance might be more critical. In this case, stainless steel or high carbon stainless steel can provide a balance between performance and maintenance requirements.

Remember, selecting the best steel for your knife ultimately comes down to understanding your specific needs and preferences, ensuring that the knife is well suited for its intended use.

Glossary of Terms

Alloys and Carbides

Alloys are a combination of several metals, designed to create steel superior to both traditional stainless and carbon steel. The process of alloying involves mixing different elements with the base metal (iron) to produce specific properties, such as increased hardness, wear resistance, corrosion resistance, or toughness.

Carbides are hard particles that form within steel during the manufacturing process. They contribute significantly to a knife’s ability to maintain a sharp edge. Carbides are formed when carbon combines with other elements like vanadium, chromium, or tungsten during the steel production process.

- Alloy Examples: Some common alloys used in knife-making include stainless steel (iron mixed with chromium to prevent rust) and high-carbon steel (iron mixed with larger amounts of carbon for increased hardness).

- Carbide Examples: Vanadium carbides (VC), chromium carbides (CrC), and tungsten carbides (WC) are some prevalent carbides that impact a knife’s performance.

Steel Naming Conventions

Different naming conventions are used in the knife industry to label various steel types. These conventions depend on the steel’s composition, the manufacturing process, and sometimes the company producing the steel.

- Carpenter: Carpenter Technology Corporation is a steel manufacturer known for producing high-quality stainless steels and specialty alloys for knives. They use their own naming conventions, such as CTS-XHP, which incorporates “CTS” (Carpenter’s acronym), followed by the steel’s properties and composition.

- Metric: The metric naming convention for steel uses a combination of letters and numbers to describe the steel’s characteristics. For example, “8Cr13MoV” indicates that the steel contains 0.8% carbon (C), 13% chromium (Cr), and small percentages of molybdenum (Mo) and vanadium (V).

It is essential to understand these terms and conventions when discussing knife steel, as it helps accurately describe and differentiate the various steel types’ qualities and performance capabilities.

Final Thoughts

In the realm of knife making, the choice of steel plays a crucial role in determining the quality and performance of the final product. It is essential to select the appropriate steel type based on the intended use and desired characteristics of the knife.

Various steel compositions offer different advantages, such as wear resistance, corrosion resistance, edge retention, and toughness. Considering all of these factors, it becomes clear that the best steel for a specific knife is highly dependent on an individual’s specific needs and preferences.

In conclusion, the process of selecting the optimal knife steel should involve a careful evaluation of the desired traits and an understanding of the steel’s inherent properties. By taking the time to research and assess the vast array of available steels, one can ensure that the knife they purchase or craft is well-suited to meet their demands and expectations.

How Sharp Is A Scalpel? (Is It Sharper Than A Razor?)

Can You Shave With A Knife? (Yes, Here’s How)

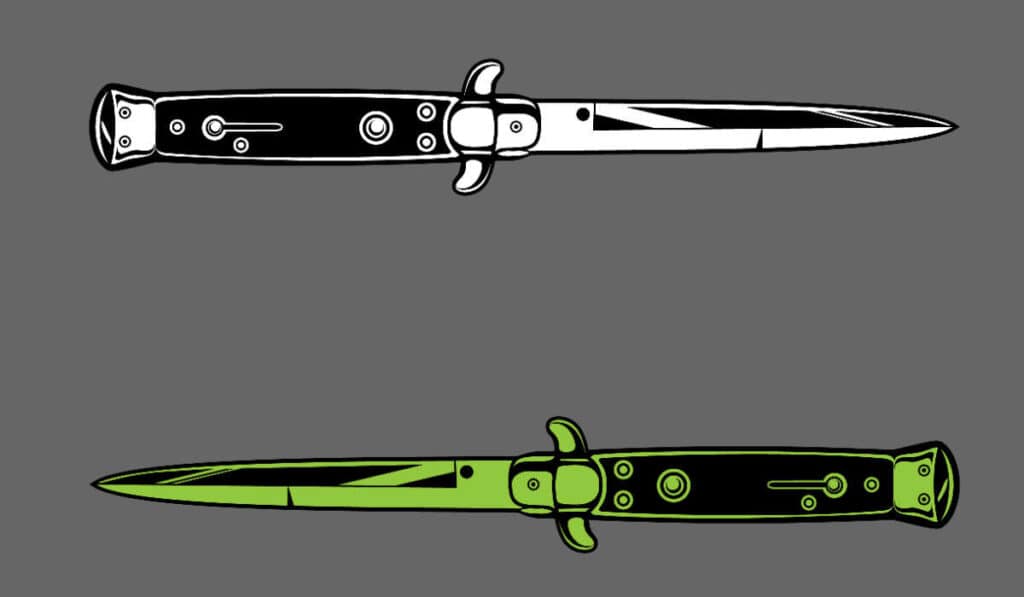

Are Switchblades Illegal? (It Depends…)

Are Butterfly Knives Illegal? (In Which States & Why…)

Why Are Gravity Knives Illegal? (Because I Want One…)

What Is A Kukri Knife Used For? (A Gruesome History Trip)

Can I Travel with Cooking Knives? (Yes, here’s how…)

Can a Sikh Legally Carry a Knife? (Kirpan Laws & Issues)

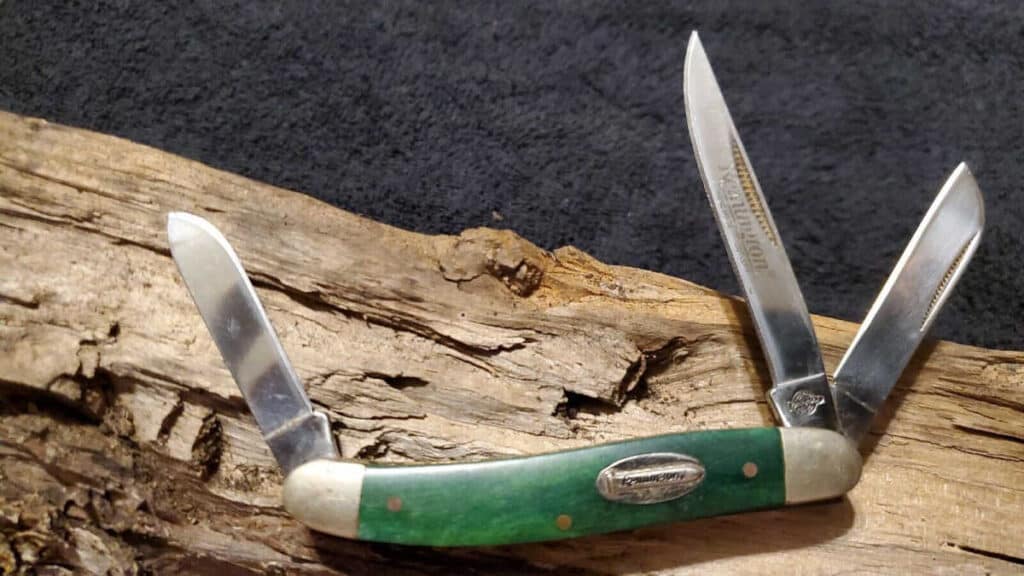

What Are the 3 Blades on a Pocket Knife For? (Answered)

As an Amazon Associate I earn from qualifying purchases.